PROJECT

Achieving carbon neutrality by 2031

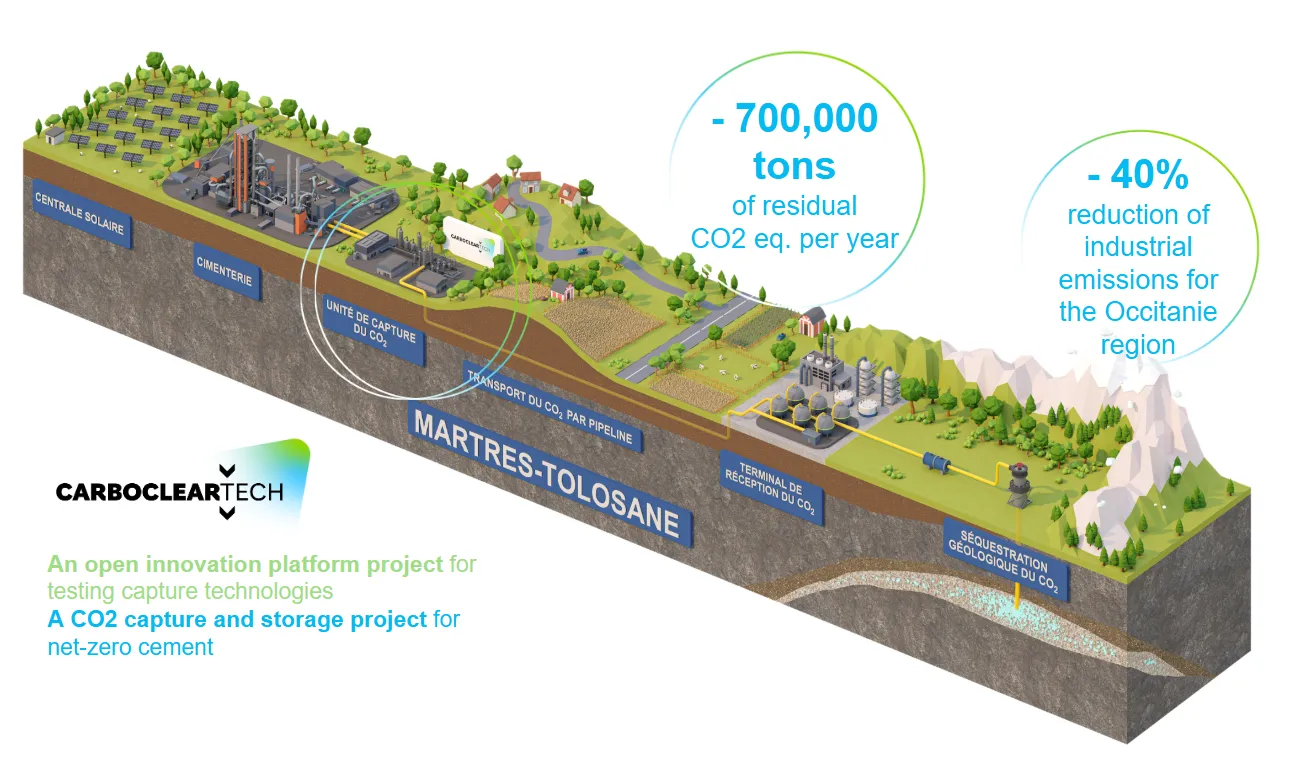

At Martres-Tolosane in Haute-Garonne, the Holcim Group is undertaking a major investment programme to capture and store residual carbon emissions linked to the cement-making process. With CarboClearTech, the site will achieve carbon neutrality by 2031, ushering in a new carbon-free era for the entire construction sector, which already benefits from the low-carbon cements produced at Martres-Tolosane.

This is the first CO2 capture site in South-Western France, enabling the development of a CO2 capture, sequestration and utilization value chain that will accelerate the decarbonisation of industry in Occitanie and Nouvelle Aquitaine regions.

ASSETS

A significant fall in emissions: 700,000 tons of CO2 captured every year

The Martres-Tolosane cement plant is one of the most modern in France thanks to recent investments totaling €124 million. While the site already meets the highest energy standards (optimized electricity consumption, replacement of fossil fuels with alternative fuels), the residual CO2 emissions capture unit will guarantee carbon neutrality as of 2031. With more than 700,000 tons of CO2 captured and therefore avoided per year, CarboClearTech will reduce industrial emissions in the Occitanie region by 40%.

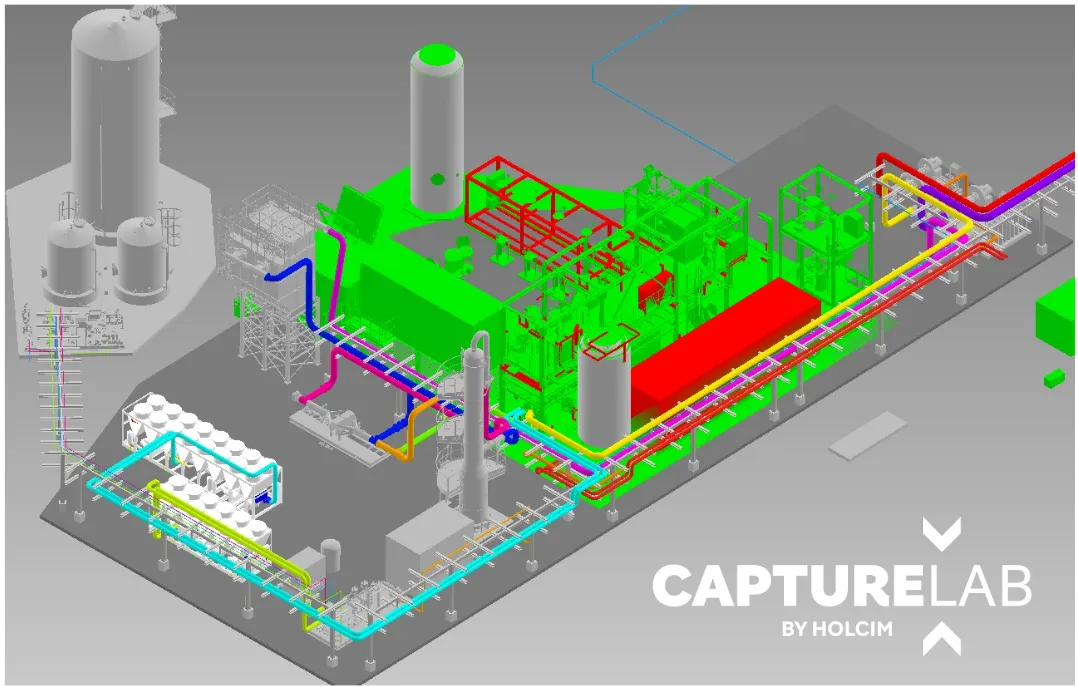

Open Innovation to advance CO2 capture technologies

From 2025, the cement plant will host an open innovation platform for testing capture technologies. Thanks to a “plug and play” design, players in the CO2 processing chain - researchers, start-ups, large companies, etc. - will have access to an industrial test bench, the only one of its kind in France, to test their innovations on a real scale and over a significant period of time.

TERRITORY

An impact on the decarbonisation of the entire construction sector

In addition to directly enhancing the vitality and economic attractiveness of the region by contributing to its green growth, CarboClearTech will be a powerful lever for the decarbonisation of the construction industry. This decarbonisation of cement will thus help to preserve the know-how and jobs of the construction sector (nearly 270,000 jobs for the regions of Occitanie and Nouvelle-Aquitaine).

An innovative CO2 capture system, a first for South-West Europe

CarboClearTech is based on an innovative technological process, developed in partnership with a world leader in industrial gases. The CO2 will be captured during the calcination of limestone, then transported in gas pipelines to be definitively injected in sequestration sites located in the Pyrenean foothills. As the first CO2 capture site in south-western Europe, CarboClearTech is making it possible to develop CO2 capture, sequestration and utilization processes in an area where these technologies are not yet in use.

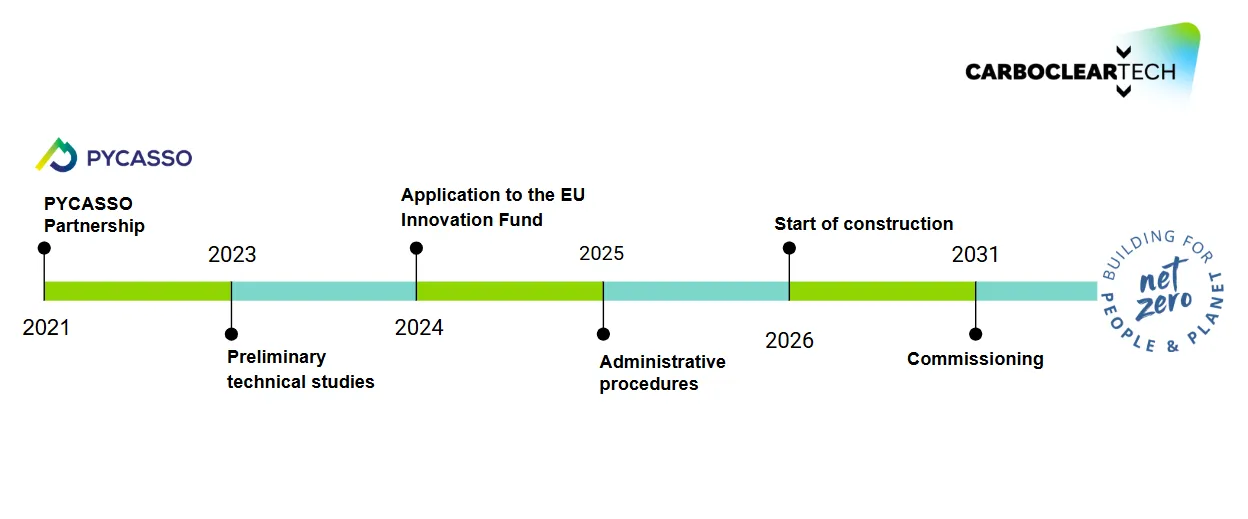

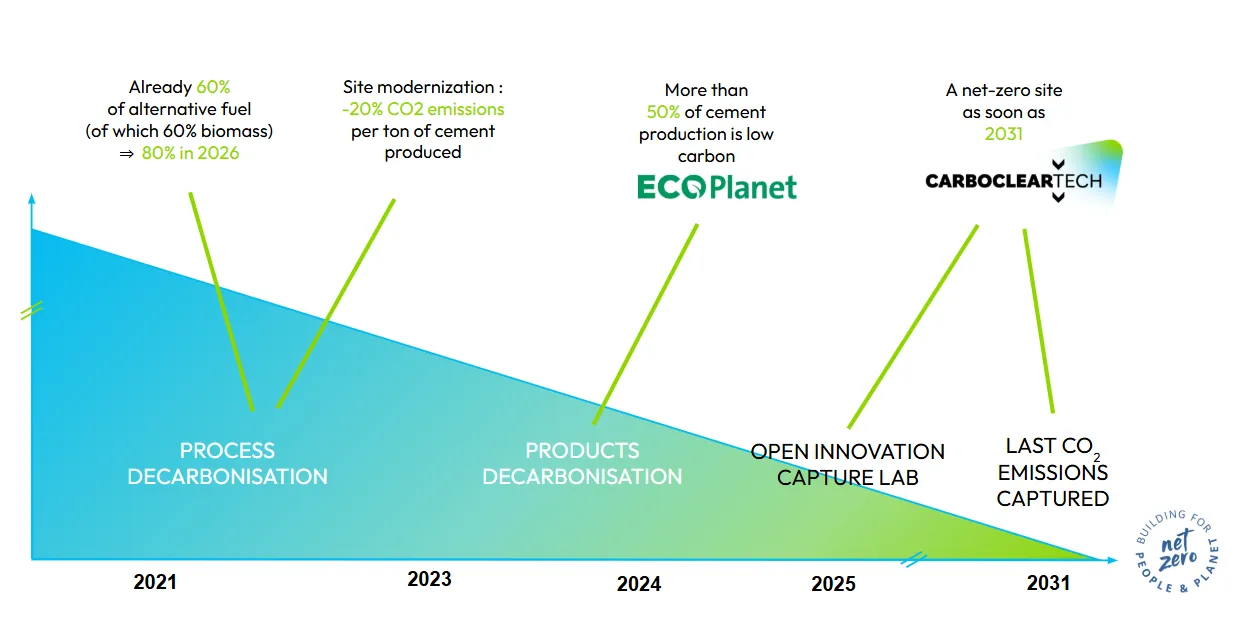

TIMELINE

FACTORY

A proactive decarbonisation trajectory

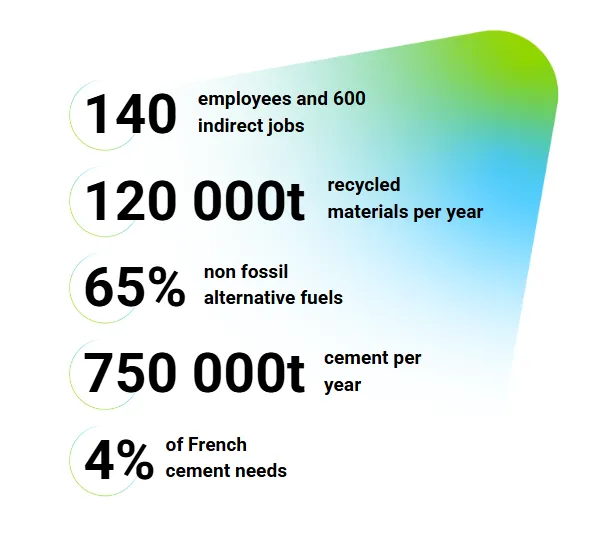

The Martres-Tolosane cement factory is a major site for the Holcim group in France, producing 750,000 tons of cement per year, amounting for 4% of the country's production. The factory is located in the heart of the Southwest, supplying everyday construction sites, as well as exceptional structures, from Bordeaux to Narbonne. The factory is also at the cutting edge of low-carbon cements: in 2023, it launched ECOPlanet cement with a 58% reduced carbon footprint (compared to CEM I Portland cement), currently used for the extension of the Toulouse metro.

Such performance is now possible thanks to the major transformation carried out in 2020-2022, consisting of the replacement of the old clinker kiln with a new firing line equipped with the best available technologies. This work has enabled the plant to drastically increase the energy recovery from waste and its recycling in the clinker: today 65% of the thermal energy comes from alternative fuels, the majority of which is biomass, with the ambition of reaching 85% by 2027.

KEY FACTS